Converting non-recyclable waste into fuel using our patented technologies

Producing advanced methanol for use in fuel blending, to meet the RED II objective.

100%

of our waste recycled.

We have the Key.

A more sustainable fuel industry

GIDARA Energy’s first production facility will be located in the Port of Amsterdam (Netherlands). Advanced Methanol Amsterdam (AMA) is destined to produce advanced methanol that meets the European biofuel mandate (RED II, June 2021) as well as local, Dutch legislation. Beyond the production facility, the site will also be home to a testing facility, knowledge centre, and pilot plant. The production facility is expected to be fully operational in 2024, meeting its objective contributing to better transportation fuels and a more circular economy. Additionally, AMA’s complete value chain, including suppliers and customers, are in the vicinity of the facility, thus supporting local employment and the local economy.

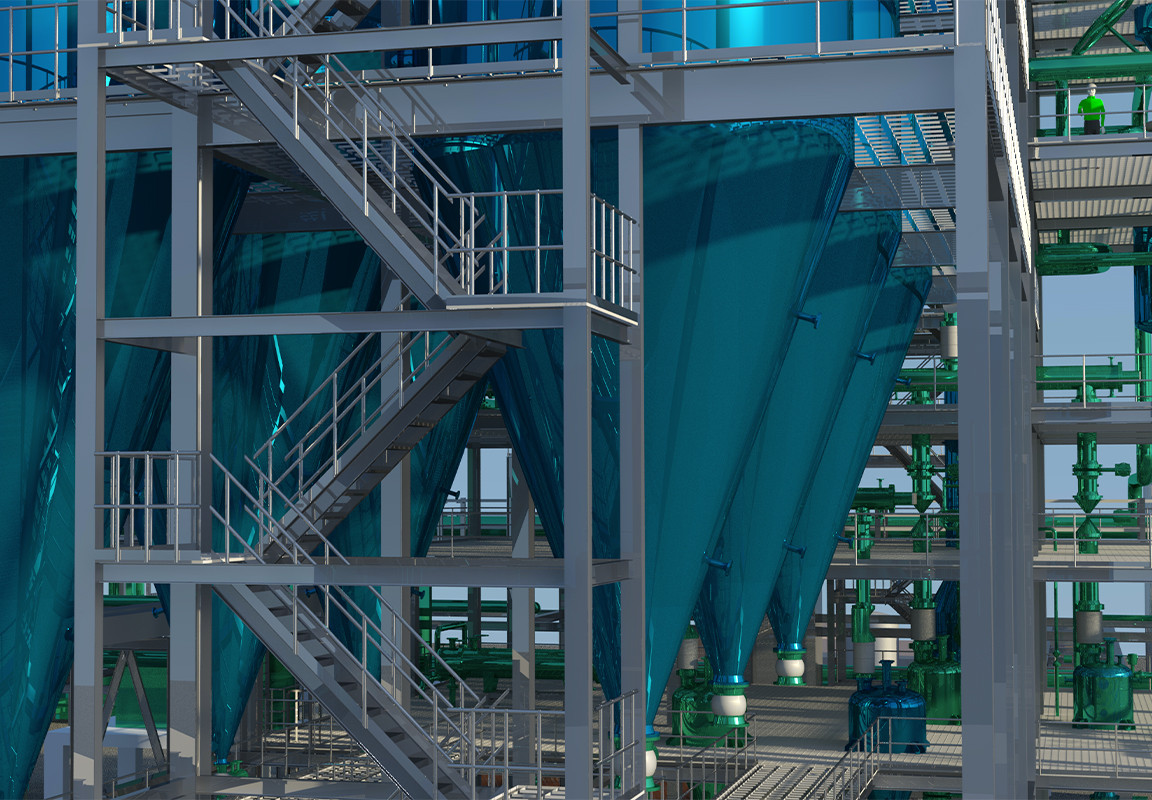

State-of-the-art facility in the Port of Amsterdam

Advanced Methanol Amsterdam (AMA) is located in the Port of Amsterdam's Biopark, a development location for producers of renewable fuels. Once completed, AMA will be the flagship production site for GIDARA Energy.

AMA will produce an average of 87.500 tonnes of advanced methanol per year by converting non-recyclable waste equivalent to that of 290.000 households yearly, which otherwise would be landfilled

or incinerated.

The advanced methanol will be used for fuel blending and therefore meet governmental objectives to achieve CO2 emission reductions as defined in the RED II and translated in national legislations. The produced renewable fuel will replace fossil-based fuels, creating significant carbon savings.

The facility will be connected to the Technical University Darmstadt and a major local university, all working towards the same goals.

Circular Economy

By giving a second life to non-recyclable waste that is currently being incinerated or landfilled, GIDARA Energy is contributing to the circular economy by repurposing waste to replace fossil fuels.

Additional benefits of GIDARA Energy's approach are the supply of excess CO2 to local greenhouse horticulture, the recovery of solid residues used for making bio-composite cement filling, and minimising the use of precious water resources.

Our patented HTW® gasification technology

The High Temperature Winkler (HTW®) technology is one of the most developed gasification technologies. In 2019, GIDARA Energy acquired the HTW® from ThyssenKrupp, further developing the technology for modern applications.

The focus of GIDARA Energy is reliability. Our technology has been applied in operating factories for more than 10 years, whereby feedstock was derived from M&W, waste wood, sewage sludge and RDF.

Whereas some other technology owners have only achieved weeks of continuous operations as a maximum or take a non-proven process for gas treatment and methanol product, we rely on multi-decade proven operation.

Our goal is to use our technology to set up a commercially viable plant that helps the world with the waste problem.

People, Planet, Profit.